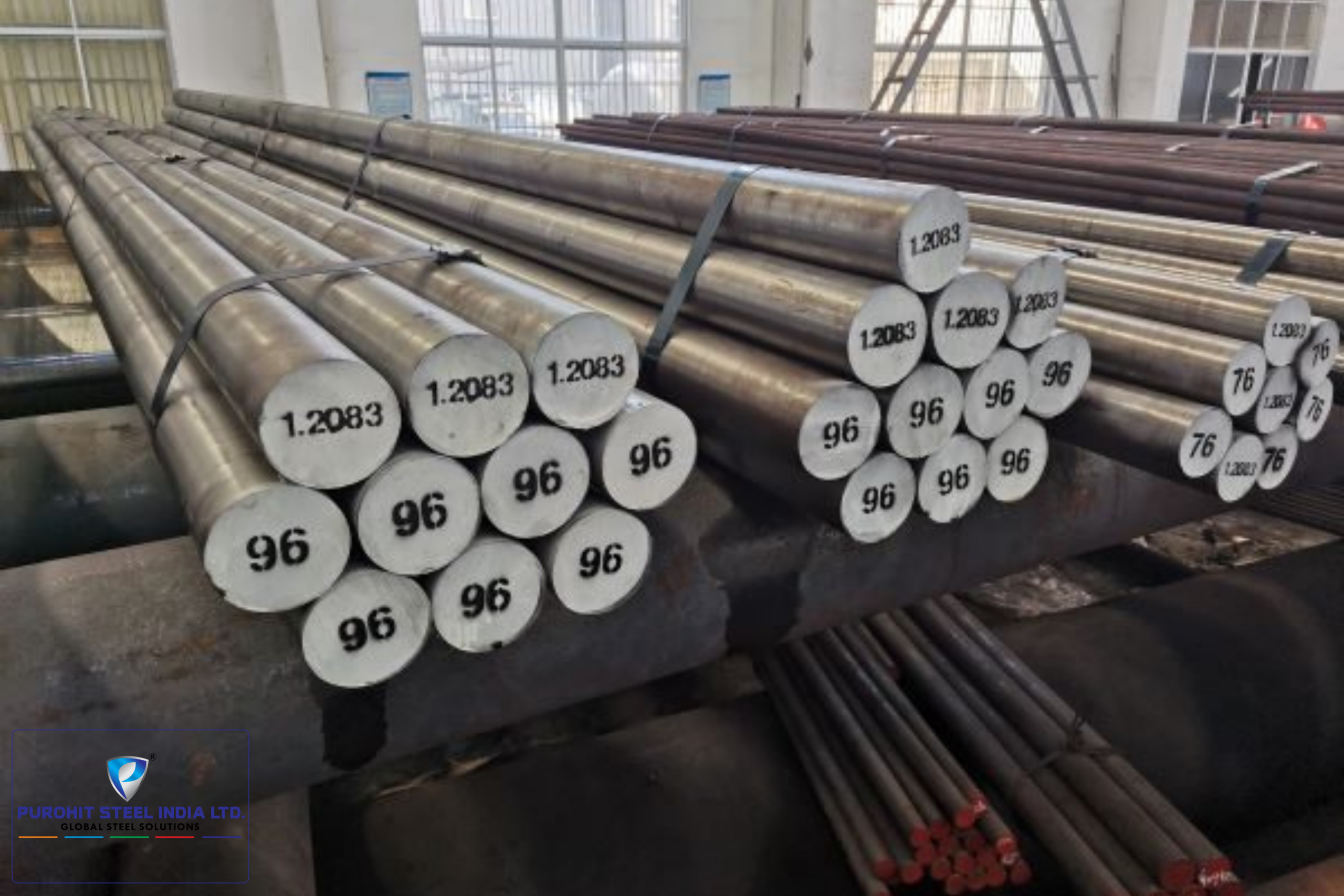

Grade 1.2083 ESR

Grade 1.2083 ESR, also known as X40Cr14 ESR, is a high-purity, corrosion-resistant tool steel specifically designed for plastic mould applications that require premium polishability, long tool life, and exceptional cleanliness. The ESR (Electro Slag Remelting) process produces an extremely pure steel structure by removing inclusions and refining the grain structure.

Because of this, 1.2083 ESR is considered a high-end stainless mould steel, superior to conventional 1.2083 due to improved toughness, homogeneity, and surface quality.

It typically comes in a pre-hardened condition (30–36 HRC) or in annealed form for later heat treatment up to 48–52 HRC, depending on application requirements.

Key Properties of 1.2083 ESR

1. Excellent Corrosion Resistance

With 13–14% chromium and ultra-clean ESR structure, the steel resists:

a. Rust from water cooling channels

b. Humidity and condensation

c. Corrosive gases during moulding

d. Chemical attack from aggressive plastics

This reduces maintenance and increases mould life significantly.

2. Superior Polishability

Thanks to ESR refining, 1.2083 ESR offers:

a. Optical-grade polishability

b. Zero micro-tears

c. Crystal-clear mould surface reproduction

It is ideal for transparent, glossy, and cosmetic plastic parts such as lenses, covers, and medical components.

3. High Hardness & Wear Resistance

When hardened (48–52 HRC), it maintains:

a. Strong wear resistance

b. High surface durability

c. Excellent dimensional stability

Even at pre-hardened levels, it provides strong performance for demanding moulds.

4. Excellent Cleanliness & Machinability

The ESR process creates a fine, uniform microstructure that improves:

a. Machinability

b. EDM finishing

c. Texturing and laser etching

d. Tool longevity

5. Good Weldability

Compared to standard stainless mould steels, 1.2083 ESR welds more cleanly when proper stainless welding rods are used. Post-weld polishing quality is also superior.

Common Applications

1. Transparent plastic moulds (optical lenses, covers, clear containers)

2. Cosmetic & medical product moulds

3. High-gloss injection moulds

4. Blow moulds for food & hygiene packaging

5. Moulds operating in humid or corrosive environments

6. Water-contact or chemically aggressive mould applications

7. Precision mould components requiring mirror finish

Summary

1.2083 ESR is a premium, corrosion-resistant, high-purity stainless mould steel optimized for applications demanding excellent polishability, long-lasting performance, and dimensional stability. The ESR process makes it ideal for high-gloss surfaces, transparent plastics, and precise moulding operations where surface quality is critical.