Grade 1.2085

Grade 1.2085 steel, often referred to as 420 Modified, stands as a testament to the artistry of metallurgical engineering, offering a unique blend of strength, corrosion resistance, and machinability. This steel alloy, with its distinctive composition and properties, serves as a versatile material with applications ranging from precision engineering to tool and die making.

At its core, Grade 1.2085 steel embodies a carefully balanced alloy composition, comprising chromium, carbon, manganese, and silicon, along with additional elements for enhanced performance. This combination results in a steel with excellent hardness, wear resistance, and dimensional stability, making it well-suited for applications requiring precision machining and high surface finish.

One of the standout features of Grade 1.2085 steel is its exceptional corrosion resistance, particularly in environments where exposure to moisture, chemicals, or abrasive substances is prevalent. The chromium content in the alloy forms a protective oxide layer on the surface, shielding the steel from corrosion and ensuring long-term durability and reliability in harsh operating conditions.

Moreover, Grade 1.2085 steel offers superior machinability, allowing for ease of fabrication and customization to specific design requirements. Its uniform microstructure and fine grain size enable precise machining and shaping, reducing production lead times and costs while ensuring dimensional accuracy and surface finish.

Furthermore, Grade 1.2085 steel embodies the principles of sustainability and resource efficiency. Its high recyclability and low carbon footprint make it a preferred choice for green engineering initiatives, contributing to the conservation of resources and reduction of environmental impact.

In essence, Grade 1.2085 steel represents a fusion of art and science in materials engineering, offering unmatched performance, reliability, and versatility for diverse applications. As industries continue to evolve and innovate, 1.2085 steel stands ready to meet the challenges of tomorrow, driving progress and shaping the future of engineering materials. Contact Us.

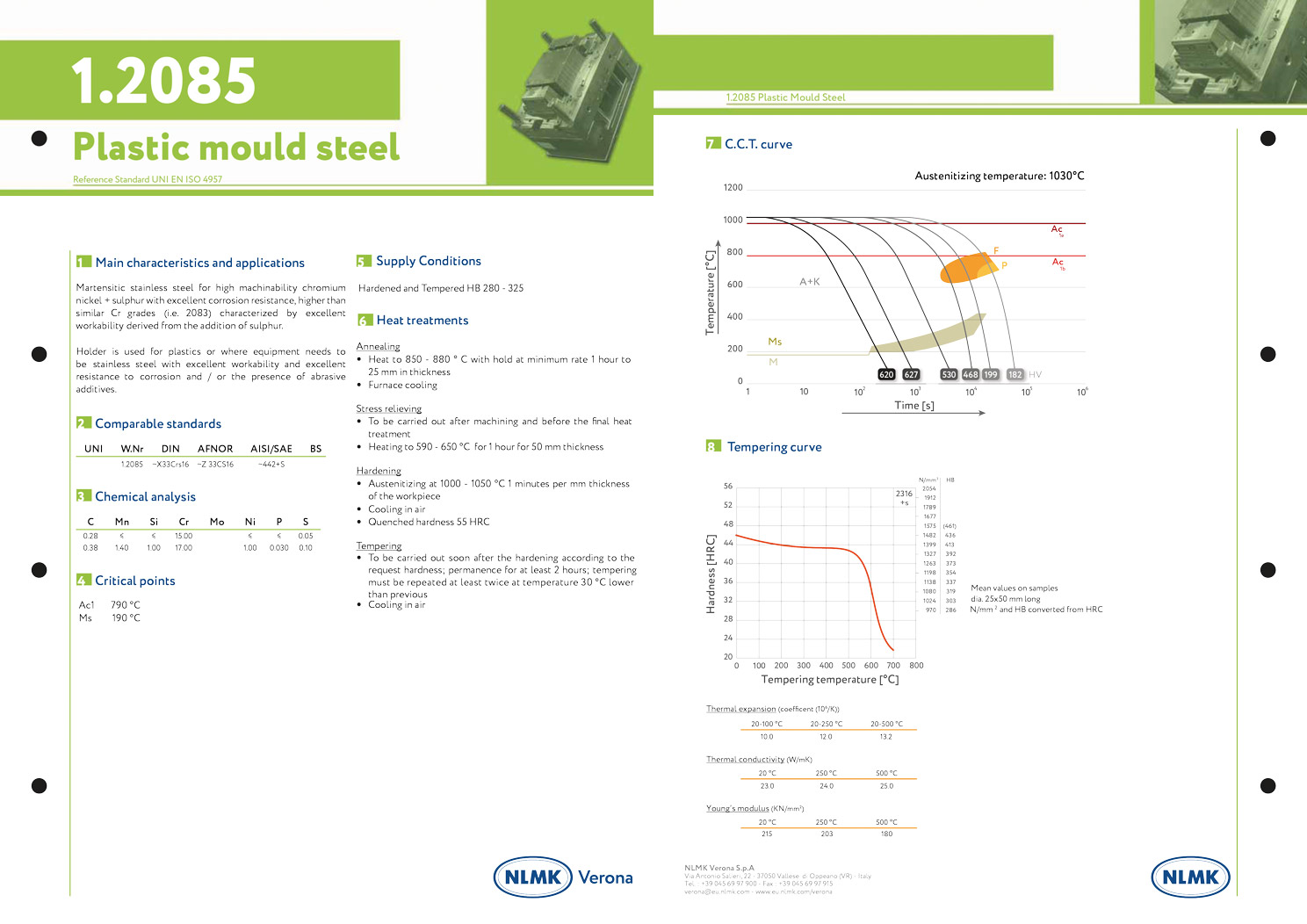

Chemical Composition:

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.38 | 1.40 | 1.00 | 17 | 1.00 | – | 0.030 | 0.10 | – | – | – |

HARDNESS:

| HB | HRC |

| 280-325 | 29-33 |

TECHNICAL PROPERTIES :

| Machinability | Polishability | Texturability |

| ●●●● | ●● | ● |

Applications:

As holder, Used for plastic or where equipment needs to be stainless steel with excellent workability and excellent resistance to corrosion and or presence of abrasive additives.