Grade D2/ 1.2379/ Dumac 11

D2/ 1.2379/ Dumac 11, is a high-carbon, high-chromium air-hardening cold-work tool steel widely used in tooling applications requiring excellent wear resistance, high hardness, long life, and good dimensional stability.

It belongs to the AISI D-series and is considered an upgraded, tougher variant compared to D3 (1.2080).

D2 offers an excellent balance of wear resistance + toughness, making it one of the most versatile and commonly used cold work tool steels worldwide.

Key Properties of D2 / 1.2379 / Dumac 11

1. High Wear Resistance

D2 contains a large volume of chromium carbides, giving it outstanding resistance to:

a. Abrasive wear

b. Sliding wear

c. Repetitive friction

This makes it ideal for tools that undergo heavy mechanical usage.

2. High Hardness (58–62 HRC)

After proper heat treatment, D2 reaches very high hardness, providing:

a. Long tool life

b. High accuracy

c. Sharp cutting edges that last longer

3. Better Toughness than D3

While D3 is extremely wear-resistant but brittle, D2 provides:

a. Higher shock resistance

b. Better edge strength

c. Less chipping and cracking

This makes D2 suitable for more demanding operations.

4. Excellent Dimensional Stability

As an air-hardening steel, D2 undergoes minimal distortion during heat treatment.

This is important for high-precision tools.

5. Moderate Corrosion Resistance

Its 12% chromium gives partial corrosion resistance, though it is not stainless steel.

It performs better in humid environments compared to other tool steels.

6. Good Machinability in Annealed Condition

Despite its high alloy carbide content, D2 can be machined reasonably well before hardening.

EDM and grinding are commonly used for finishing.

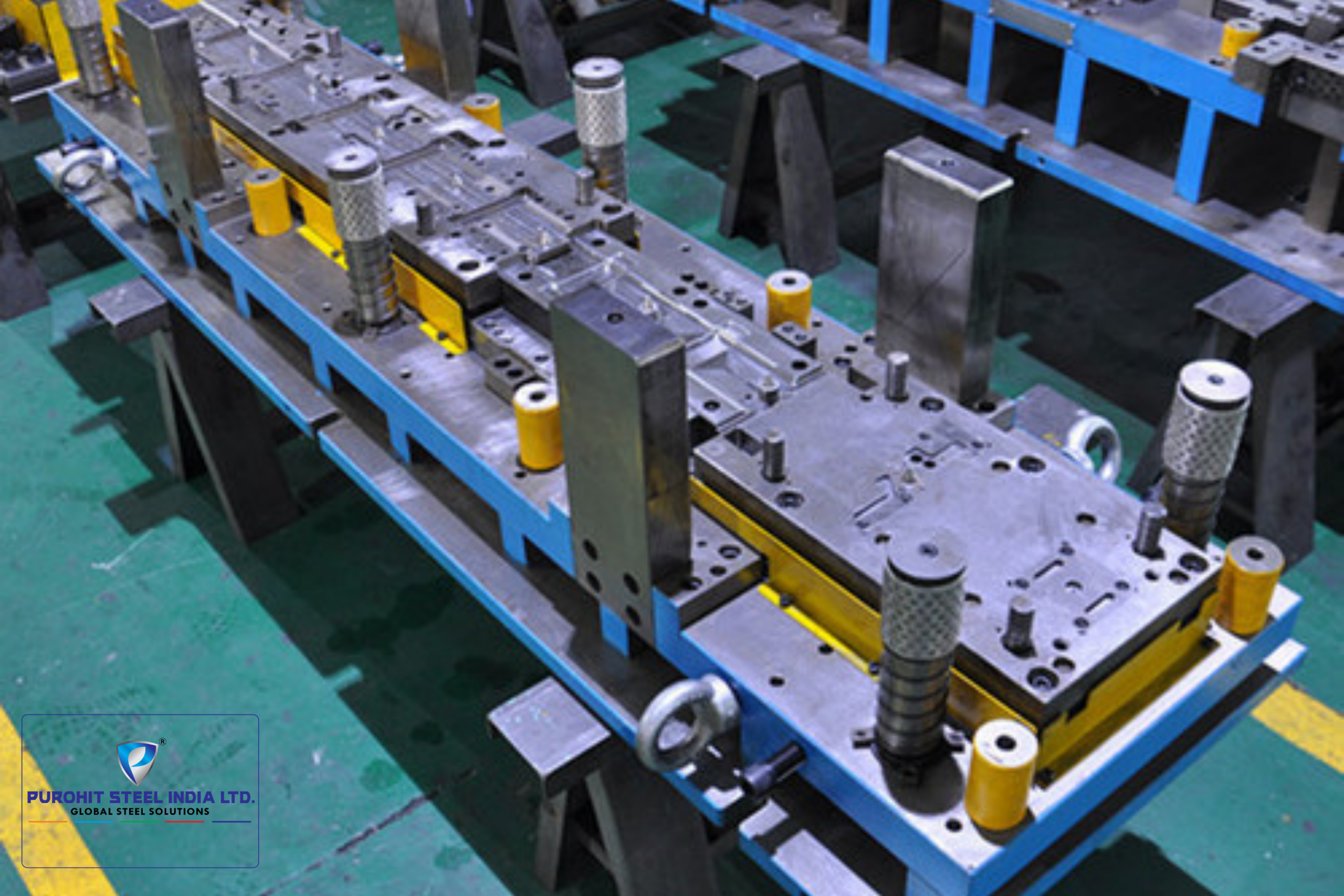

Common Applications

1. Punches & dies (blanking, piercing, stamping)

2. Shear blades & slitting cutters

3. Thread rolling dies

4. Forming & drawing tools

5. Trimming & cutting knives

6. Cold forging tools

7. Industrial machine parts

8. Pelletizer knives

9. Wood & leather cutting tools

Summary

D2/ 1.2379/ Dumac 11 is a premium cold work tool steel known for its superior wear resistance, high hardness, and very good toughness. It outperforms D3 in durability and shock loading while maintaining excellent edge retention.

Because of its balanced properties, D2 remains one of the most widely used tool steels for cutting, forming, stamping, and abrasive tooling applications.