PM Grade Steels

PM grade steels, or powder metallurgy steel, represent a fascinating evolution in metallurgical engineering. These steels are crafted through a meticulous process that involves the precise blending of metal powders, followed by compacting them under immense pressure and sintering at high temperatures. The result is a material with exceptional properties and uniformity, setting it apart from conventionally manufactured steels.

One of the key advantages of PM grade steels lies in their enhanced purity and homogeneity. Traditional steel manufacturing methods often introduce impurities and irregularities during the casting or forging process. In contrast, powder metallurgy allows for the precise control of composition, resulting in a more consistent and reliable product. This purity translates into improved mechanical properties, such as higher strength, toughness, and wear resistance.

Moreover, PM grade steel offer designers and engineers greater flexibility in material design. By adjusting the composition and processing parameters, specific properties can be tailored to meet the requirements of diverse applications. Whether it’s high-strength components for automotive or aerospace industries, corrosion-resistant parts for marine environments, or wear-resistant tooling for manufacturing, PM grade steels can be customized to excel in various conditions.

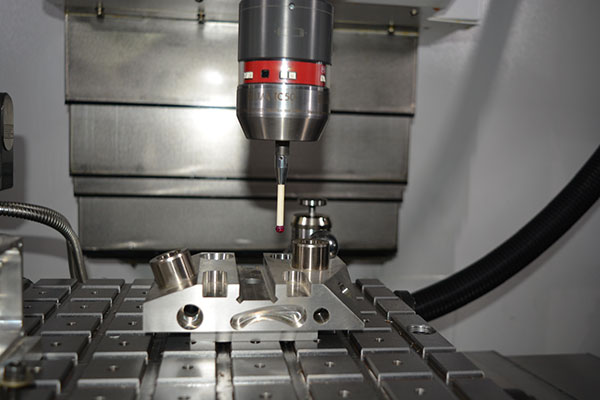

The fine microstructure of PM grade steel also contributes to their superior performance. The uniform distribution of alloying elements and fine grain size result in enhanced fatigue resistance and dimensional stability. Additionally, these steels often exhibit improved machinability compared to conventional counterparts, reducing manufacturing costs and lead times.

Despite their numerous advantages, PM grade steels are not without challenges. The initial investment in powder metallurgy equipment and technology can be substantial, limiting widespread adoption, particularly among smaller manufacturers. Additionally, the complexity of the powder metallurgy process requires expertise in material science and metallurgical engineering.

Nevertheless, the unique combination of properties offered by PM grade steel continues to drive research and development efforts in the field of materials science. As advancements in powder metallurgy techniques and understanding of material behavior progress, PM grade steels are poised to play an increasingly vital role in shaping the future of engineering and manufacturing.

PM grade tool steel is a high-alloyed PM high-speed steel suitable for very demanding cold work applications and for cutting tools. The high carbon and alloying content, Co, Mo, W and V, gives an extremely high-compressive strength combined with a very suitable abrasive wear-resistance. Contact us.