VR STAINLESS

VR Stainless represents a ground breaking concept in the realm of this steel, embodying the convergence of innovation, performance, and sustainability. This advanced material redefines the boundaries of what’s achievable in stainless steel alloys, offering a unique combination of strength, corrosion resistance, and environmental consciousness.

At its core is crafted through a proprietary alloying process that optimizes the properties of this steel for maximum performance and durability. Enriched with elements such as chromium, nickel, and molybdenum, along with advanced micro-alloying additions, this steel alloy exhibits exceptional corrosion resistance, even in the harshest environments.

One of the defining features is its superior strength-to-weight ratio, which enables the design of lighter and more efficient structures without sacrificing performance or reliability. This makes it an ideal choice for applications where weight reduction is critical, such as aerospace, automotive, and marine industries.

Moreover, VR Stainless embodies a commitment to sustainability and environmental stewardship. Its high recyclability and low carbon footprint make it a preferred choice for green engineering initiatives, contributing to the conservation of resources and reduction of environmental impact. Additionally, its long service life and minimal maintenance requirements further enhance its sustainability credentials, ensuring a more sustainable future for generations to come.

Furthermore, VR Stainless offers unparalleled versatility, with a wide range of grades and finishes available to suit various applications and aesthetic preferences. Whether it’s architectural facades, industrial equipment, or consumer products, VR Stainless provides the performance and durability required for demanding applications.

In essence, VR Stainless represents a revolution in this steel technology, offering unmatched performance, durability, and sustainability for critical applications in diverse industries. As industries continue to evolve and innovate, VR Stainless stands ready to meet the challenges of tomorrow, driving progress and shaping the future of this steel alloys. Contact Us.

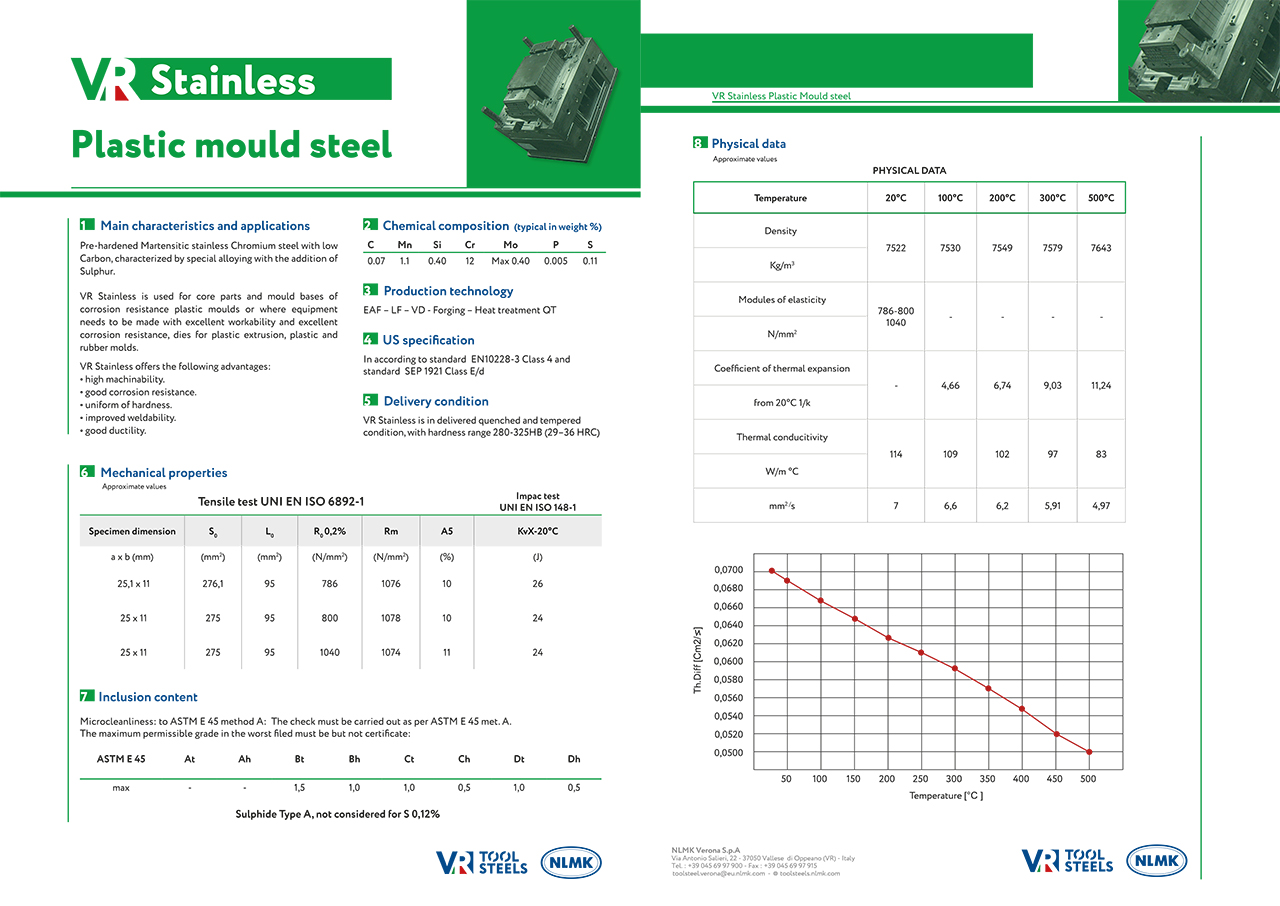

Chemical Composition:

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.07 | 1.1 | 0.40 | 12.5 | – | 0.40 | 0.005 | 0.11 | – | – | – |

HARDNESS:

| HB | HRC |

| 280-325 | 29-33 |

TECHNICAL PROPERTIES :

| Machinability | Polish ability | Texturability |

| ●●●●● | ●● | ● |

Applications:

As holder, it is used for plastic and rubber moulds.