Grade 1.2738 Steels

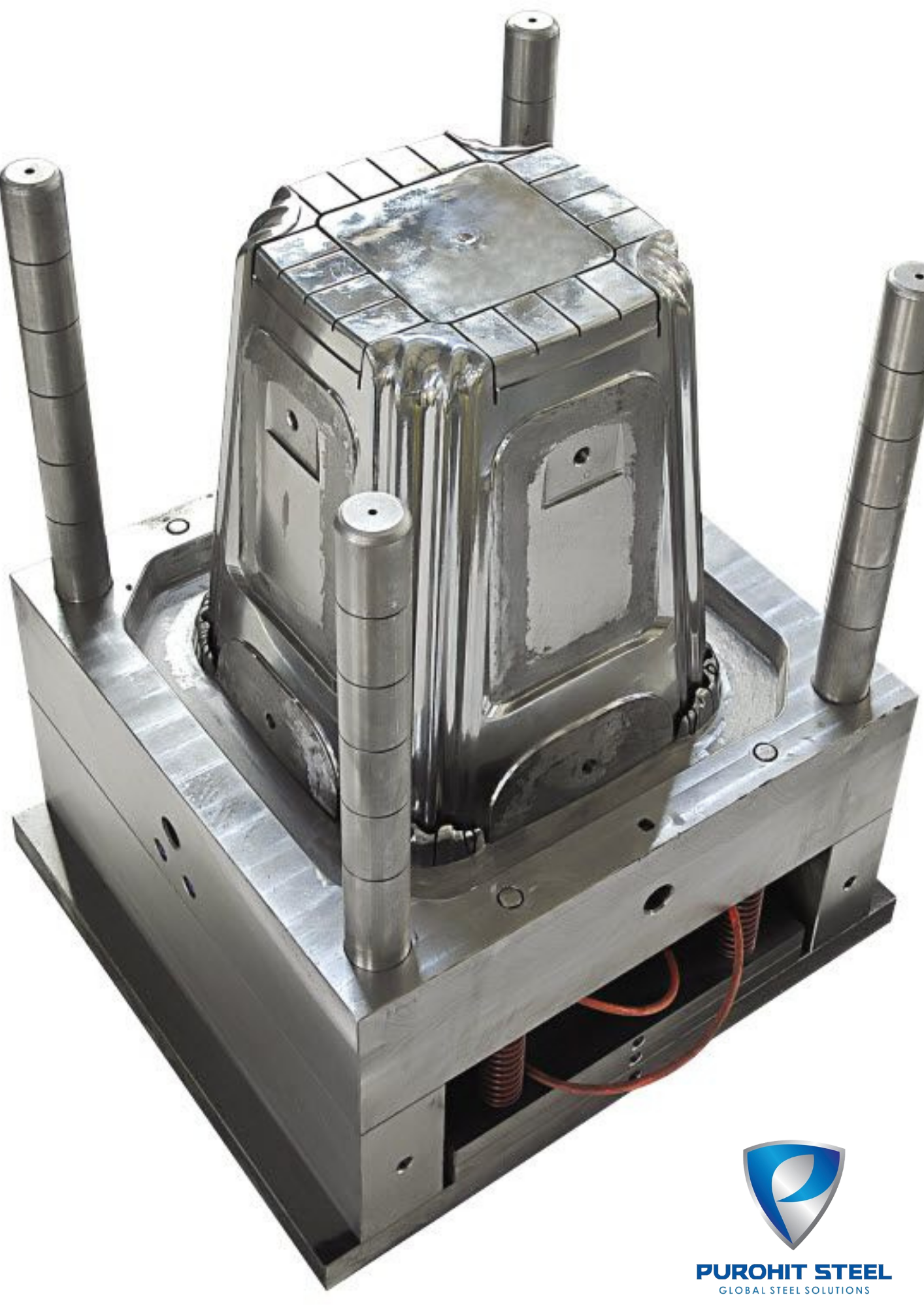

Grade 1.2738 steels, also known as P20+Ni or 718 steel, epitomize the epitome of precision and reliability in the world of plastic injection molding. These steels are meticulously engineered to withstand the rigorous demands of high-performance molding processes, offering a unique blend of hardness, toughness, and dimensional stability that sets them apart as the material of choice for critical mold applications.

At the core of Grade 1.2738 steels lies a sophisticated alloy composition, carefully calibrated to optimize performance under the harsh conditions of plastic injection molding. Enriched with elements such as chromium, nickel, and molybdenum, along with a precise amount of carbon, these steels exhibit exceptional hardness and wear resistance, ensuring long-lasting tool life and consistent part quality.

One of the key advantages of Grade 1.2738 steels is their outstanding machinability and polishability. Their fine microstructure and uniform distribution of alloying elements allow for effortless machining and polishing, enabling the creation of intricate mold cavities and complex part geometries with unparalleled precision. This superior surface finish not only enhances the aesthetic appeal of molded parts but also reduces post-processing requirements, streamlining production and reducing costs.

Moreover, Grade 1.2738 steels boast exceptional toughness and impact resistance, crucial properties for withstanding the stresses and strains of plastic injection molding operations. Their ability to endure repeated cycles of heating and cooling without deformation or cracking ensures the reliability and longevity of molds, leading to consistent part quality and minimal downtime.

Furthermore, Grade 1.2738 steels offer excellent thermal conductivity, facilitating rapid heat transfer during the molding process. This ensures uniform temperature distribution within the mold cavity, reducing the risk of warpage and shrinkage defects in molded parts. Additionally, their superior corrosion resistance makes them suitable for use with a wide range of plastic resins, further enhancing their versatility and applicability in various molding applications.

In essence, Grade 1.2738 steel represent the pinnacle of excellence in plastic injection molding technology, embodying the perfect balance of performance, reliability, and versatility. As industries continue to innovate and evolve, the role of Grade 1.2738 steels in shaping the future of manufacturing remains undisputed, their unparalleled properties driving efficiency, quality, and innovation in plastic molding processes. Contact Us.

Chemical Composition:

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.38 | 1.5 | 0.3 | 2 | 1 | 0.20 | 0.025 | 0.003 | – | – | – |

HARDNESS:

| HB | HRC |

| 280-325 | 29-33 |

TECHNICAL PROPERTIES :

| Machinability | Polishability | Texturability |

| ●●● | ●●● | ●●● |

Applications:

Thermoplastic injections and extrusion moulds, rubber moulds, large moulds, frames, containers.