High Speed Steel

High Speed Steel (HSS) is a class of high-performance tool steels designed to cut materials at high speeds while maintaining hardness, strength, and wear resistance — even at high temperatures.

HSS keeps its cutting edge sharp even when tools become hot due to friction.

This makes HSS the preferred material for cutting tools in industries like:

Manufacturing

Automotive

Aerospace

Tool & Die

Engineering workshops

Why High Speed Steel is Special?

1. Red Hardness

HSS maintains its hardness even at 550–650°C, allowing cutting at high speeds.

2. Wear Resistance

Strong alloy content (Tungsten, Molybdenum, Vanadium) makes tools last longer.

3. Strength & Toughness

Resists breaking and cracking under cutting forces.

4. Machinability

Easy to shape into drills, taps, cutters, end mills, and dies.

Chemical Composition

HSS typically contains:

Carbon (C) — 0.70% to 1.50%

Tungsten (W) — 6% to 18%

Molybdenum (Mo) — 3% to 10%

Vanadium (V) — 1% to 5%

Chromium (Cr) — 3% to 5%

These elements give HSS its hardness, heat resistance, and long tool life.

Popular Grades of High Speed Steel

M2 (1.3343)

The most widely used HSS grade.

Balanced toughness + hardness

Used in drills, taps, reamers, cutters

Ideal for general cutting tools

M35 (Co 5%)

Cobalt Alloyed HSS (5% cobalt)

Higher red hardness

Better for stainless steel machining

Used for premium cutting tools

M42 (Co 8%)

High Cobalt (8%) Super HSS

Exceptional heat resistance

Best for hard metals & heavy machining

High-performance drills, end mills

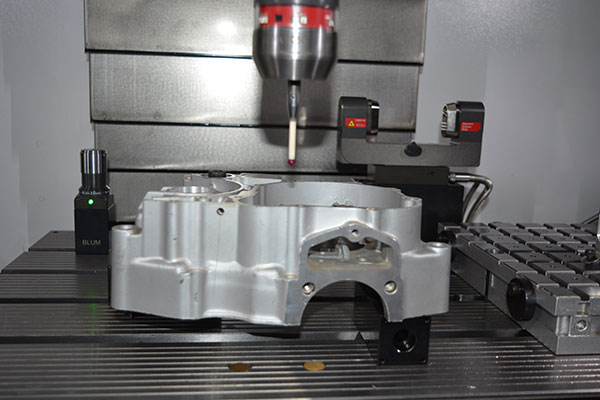

Applications of HSS

Drill bits

Taps

End mills

Reamers

Broaches

Hobs

Saw blades

Punches & dies

Turning tools

Milling cutters

High Speed Steel vs Carbide — Quick Comparison

| Property | HSS | Carbide |

| ————— | —————– | ——————————— |

| Toughness | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Heat Resistance | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Cutting Speed | Medium | Very High |

| Cost | Affordable | Expensive |

| Best For | General machining | Hard materials, precision cutting |

Why Industries Prefer HSS

1. Affordable and durable

2. Easy to sharpen

3. Suitable for most metals

4. Works well under high speed

5. Long tool life