Grade 1.2842/ O2:-

Grade 1.2842, commonly known as O2 steel, emerges as a foundational material in the realm of tool steels, embodying a remarkable blend of hardness, toughness, and dimensional stability. Crafted with precision and ingenuity, this steel alloy serves as a reliable material for critical applications in tool and die making, cold work tooling, and precision engineering.

At its core, Grade 1.2842 steel boasts an alloy composition meticulously engineered to optimize mechanical properties and enhance performance under low-temperature conditions. Enriched with elements such as manganese, chromium, and vanadium, this steel exhibits exceptional hardness, wear resistance, and dimensional stability, making it an ideal choice for tooling subjected to heavy mechanical loads and abrasive wear.

The hallmark feature of Grade 1.2842 steel lies in its superior toughness and edge retention, ensuring prolonged tool life and reduced downtime in cold work applications. Its uniform microstructure and fine grain size enable precise machining and shaping, reducing production lead times and costs while ensuring dimensional accuracy and surface finish in the final product.

Moreover, Grade 1.2842 steel offers excellent grindability, allowing for the fabrication of complex components with ease. Its fine microstructure and uniform distribution of alloying elements enable effortless machining and grinding, ensuring precise tooling and consistent part quality in the final product.

Furthermore, Grade 1.2842 steel embodies a commitment to sustainability and environmental responsibility. Its high recyclability and low carbon footprint make it a preferred choice for green engineering initiatives, contributing to the conservation of resources and reduction of environmental impact.

In essence, Grade 1.2842 steel represents a testament to human ingenuity and innovation in materials engineering, offering unmatched performance, reliability, and sustainability for critical applications in tool and die making. As industries continue to evolve and innovate, Grade O2 steel stands ready to meet the challenges of tomorrow, driving progress and shaping the future of engineering materials.

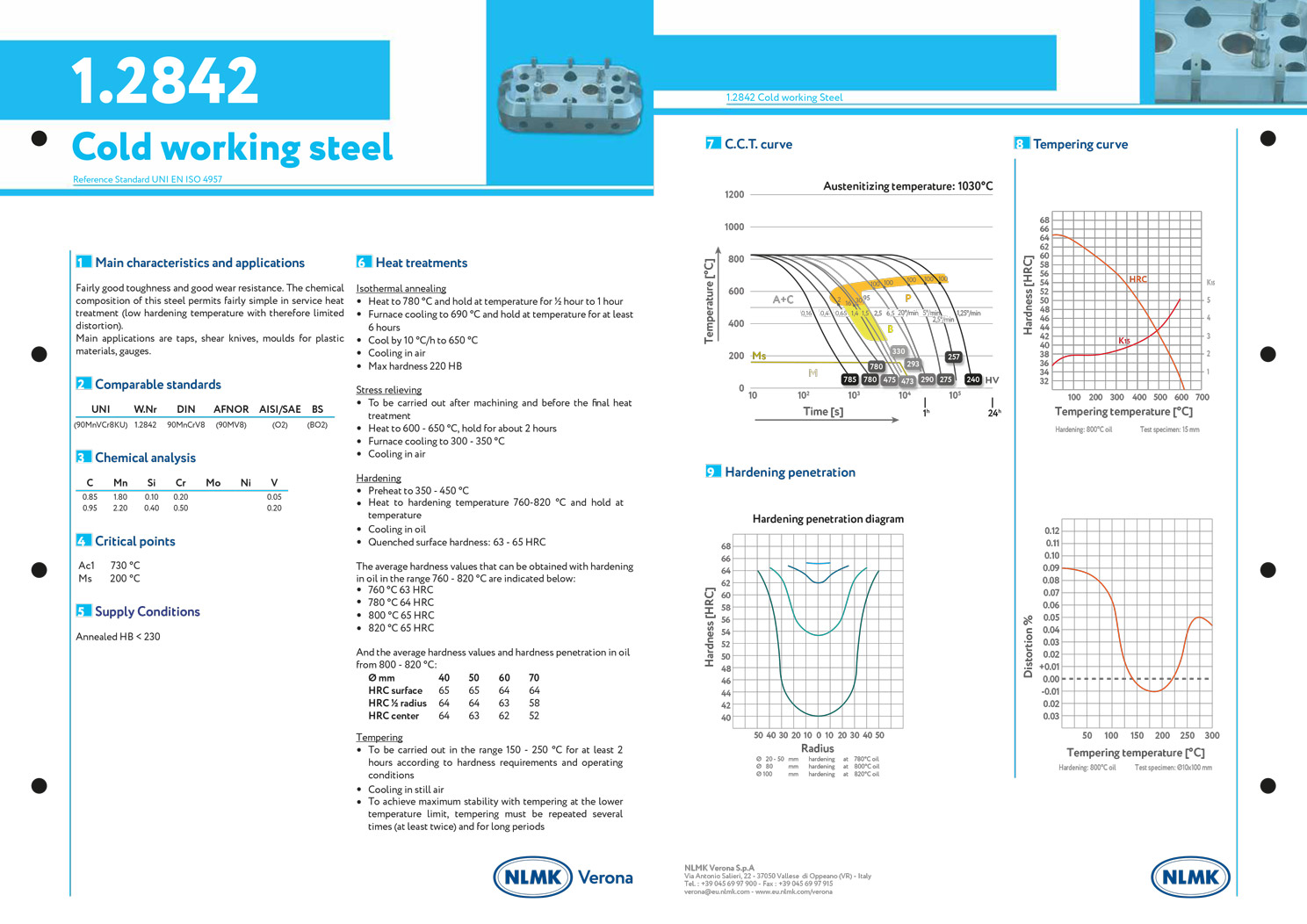

Chemical Composition :

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.95 | 2.20 | 0.40 | 0.50 | – | – | – | – | – | 0.20 |

HARDNESS :

| HB | HRC |

APPLICATIONS :

Taps, shear knives, moulds for plastic materials, gauges.