Grade DB6/ 1.2714:-

Grade DB6 / 1.2714 steel stands as a cornerstone in the world of tool and die making, embodying a harmonious blend of strength, toughness, and versatility. Crafted with precision and ingenuity, this steel alloy serves as a reliable material for critical applications in forging, extrusion, and die casting processes.

At its core, Grade DB6 / 1.2714 steel boasts a meticulously engineered alloy composition designed to optimize mechanical properties and enhance performance under demanding conditions. Enriched with elements such as chromium, nickel, molybdenum, and vanadium, this steel exhibits exceptional hardness, wear resistance, and thermal conductivity, making it an ideal choice for tooling subjected to high levels of mechanical stress and thermal cycling.

The hallmark feature of Grade DB6 / 1.2714 steel lies in its versatility, catering to a wide range of tooling applications across diverse industries. Its superior machinability and weldability enable the fabrication of complex components with ease, while its excellent dimensional stability ensures precise tooling and consistent part quality throughout the production process.

Moreover, Grade DB6 / 1.2714 steel offers exceptional toughness and impact resistance, crucial properties for withstanding the rigors of heavy-duty forging and extrusion operations. Its ability to endure repeated cycles of loading and thermal shock ensures the longevity and reliability of tooling, leading to increased productivity and reduced downtime.

Furthermore, Grade DB6 / 1.2714 steel embodies a commitment to sustainability and environmental responsibility. Its high recyclability and low carbon footprint make it a preferred choice for green engineering initiatives, contributing to the conservation of resources and reduction of environmental impact.

In essence, this steel represents a testament to human ingenuity and innovation in materials engineering, offering unmatched performance, reliability, and sustainability for critical applications in tool and die making. As industries continue to evolve and innovate, this steel stands ready to meet the challenges of tomorrow, driving progress and shaping the future of engineering materials.

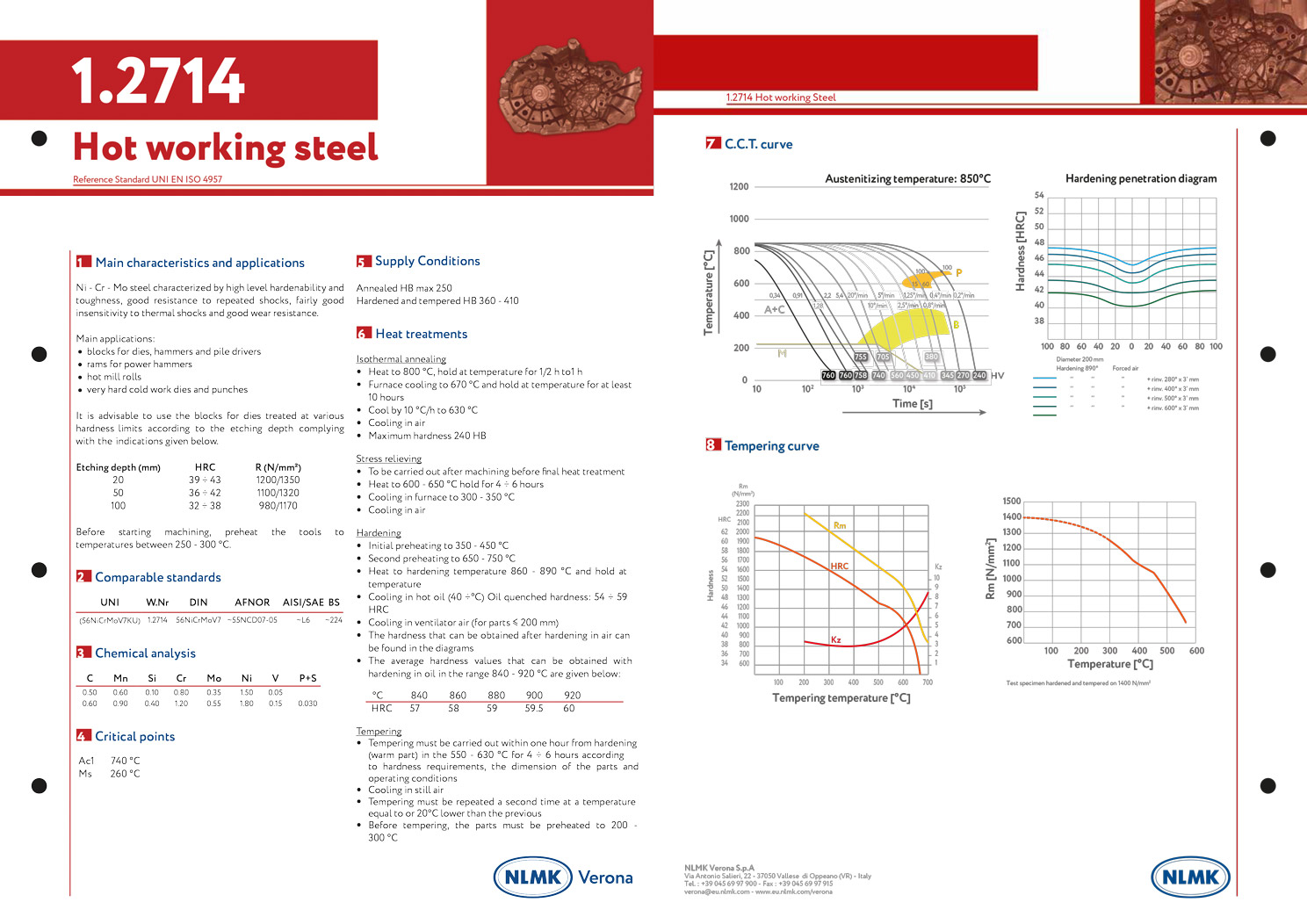

Chemical Composition :

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.6 | 0.9 | 0.4 | 1.2 | 1.8 | 0.55 | – | – | 0.030 | 0.2 | – |

HARDNESS :

| HB | HRC |

| 360 – 400 | 38 – 42 |

TECHNICAL PROPERTIES :

| Machinability | Polish ability | Texturability |

APPLICATIONS :

Blocks for dies, hammers and pile drivers, rams for power hammers, hot mill rolls, very hard cold work dies and punches