Grade H11 / 1.2343 ESR (Electroslag Remelting) steel emerges as a pinnacle of innovation and excellence in the realm of hot work tool steels, embodying the perfect blend of strength, toughness, and thermal stability. Crafted through advanced metallurgical techniques and refined through the ESR process, this steel alloy offers unmatched performance and reliability for critical applications in high-temperature environments.

At its core, Grade H11 / 1.2343 ESR steel boasts a meticulously engineered alloy composition designed to withstand the rigors of hot work applications. Enriched with elements such as chromium, molybdenum, vanadium, and silicon, this steel exhibits exceptional hardness, wear resistance, and thermal conductivity, making it an ideal choice for forging, die casting, and extrusion processes.

The hallmark feature of Grade H11 / 1.2343 ESR steel lies in its production process, which utilizes Electroslag Remelting technology to refine its microstructure and enhance its properties. This specialized process eliminates inclusions and impurities present in conventional steels, resulting in a more uniform and homogeneous material with superior mechanical properties. The result is a steel alloy that offers unmatched dimensional stability, ensuring precise tooling and consistent part quality throughout the production process.

Moreover, Grade H11 / 1.2343 ESR steel offers exceptional thermal stability, allowing for prolonged exposure to high temperatures without deformation or loss of hardness. Its ability to maintain its mechanical properties under extreme heat conditions ensures the longevity and reliability of tooling in hot work applications, leading to increased productivity and reduced downtime.

Furthermore, Grade H11 / 1.2343 ESR steel embodies a commitment to sustainability and environmental responsibility. Its high recyclability and low carbon footprint make it a preferred choice for green engineering initiatives, contributing to the conservation of resources and reduction of environmental impact.

In essence, this steel represents a revolution in materials engineering, offering unmatched performance, reliability, and sustainability for critical applications in hot work tooling. As industries continue to innovate and evolve, Grade H11 / 1.2343steel stands ready to meet the challenges of tomorrow, driving progress and shaping the future of engineering materials.

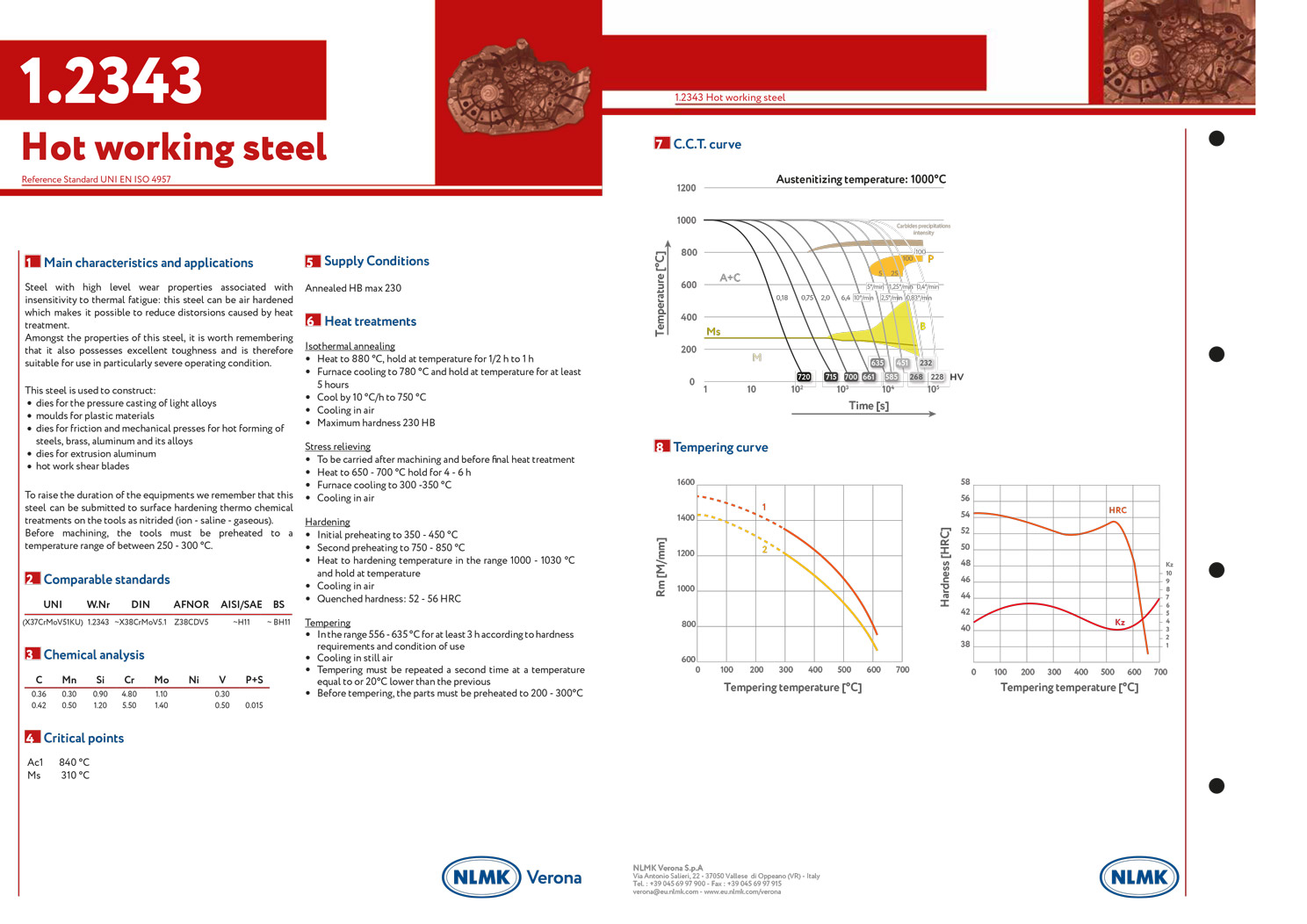

Chemical Composition :

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.42 | 0.50 | 1.20 | 5.50 | – | – | – | – | 0.015 | 0.50 | – |

HARDNESS :

| HB | HRC |

| – | 54 – 58* |

TECHNICAL PROPERTIES :

| Machinability | Polish ability | Texturability |

| ●●●● | ●●●● | ●●● |

APPLICATIONS :

Dies for the pressure casting of light alloys, moulds for plastic materials, die for friction and mechanical presses for hot forming of steels, brass, aluminium and its alloys, die for extrusion aluminium, hot work shear blades