Grade VR 400 ESR (Electroslag Remelting) steel emerges as the epitome of innovation in the realm of high-performance engineering materials, elevating the standards of strength, reliability, and precision. Born from the crucible of advanced metallurgical techniques, VR 400 ESR steel represents a paradigm shift in structural engineering, offering a unique combination of exceptional mechanical properties and superior microstructural integrity that redefines the boundaries of what’s achievable in critical applications.

At its core, VR 400 ESR steel boasts an advanced alloy composition meticulously engineered to optimize performance under extreme conditions. Enriched with elements such as chromium, molybdenum, nickel, and vanadium, along with precise control of impurities through the ESR process, these steels exhibit unparalleled strength, toughness, and resistance to fatigue and wear.

One of the standout features of VR 400 ESR steel is its exceptional purity and homogeneity, achieved through the electroslag remelting process. This specialized refining technique eliminates inclusions and segregations present in conventional steels, resulting in a more uniform microstructure and enhanced mechanical properties. The absence of internal defects not only improves the steel’s structural integrity but also ensures consistent performance under demanding conditions.

Moreover, VR 400 ESR steel offers superior machinability and weldability, allowing for the fabrication of complex components with precision and efficiency. Its fine microstructure and uniform distribution of alloying elements enable effortless machining, reducing production lead times and costs while ensuring dimensional accuracy and surface finish.

Furthermore, VR 400 ESR steel embodies the principles of sustainability and resource efficiency, with its high recyclability and low environmental footprint making it a preferred choice for green engineering initiatives. Its durability and longevity contribute to the longevity of structures, reducing the need for frequent replacements and minimizing waste.

In essence, Grade VR 400 ESR steel represents a revolution in materials science, offering unparalleled performance and reliability in critical applications where safety and precision are paramount. As industries continue to push the boundaries of innovation, VR 400 ESR steel stands as a testament to human ingenuity, pushing the limits of what’s achievable in structural engineering.

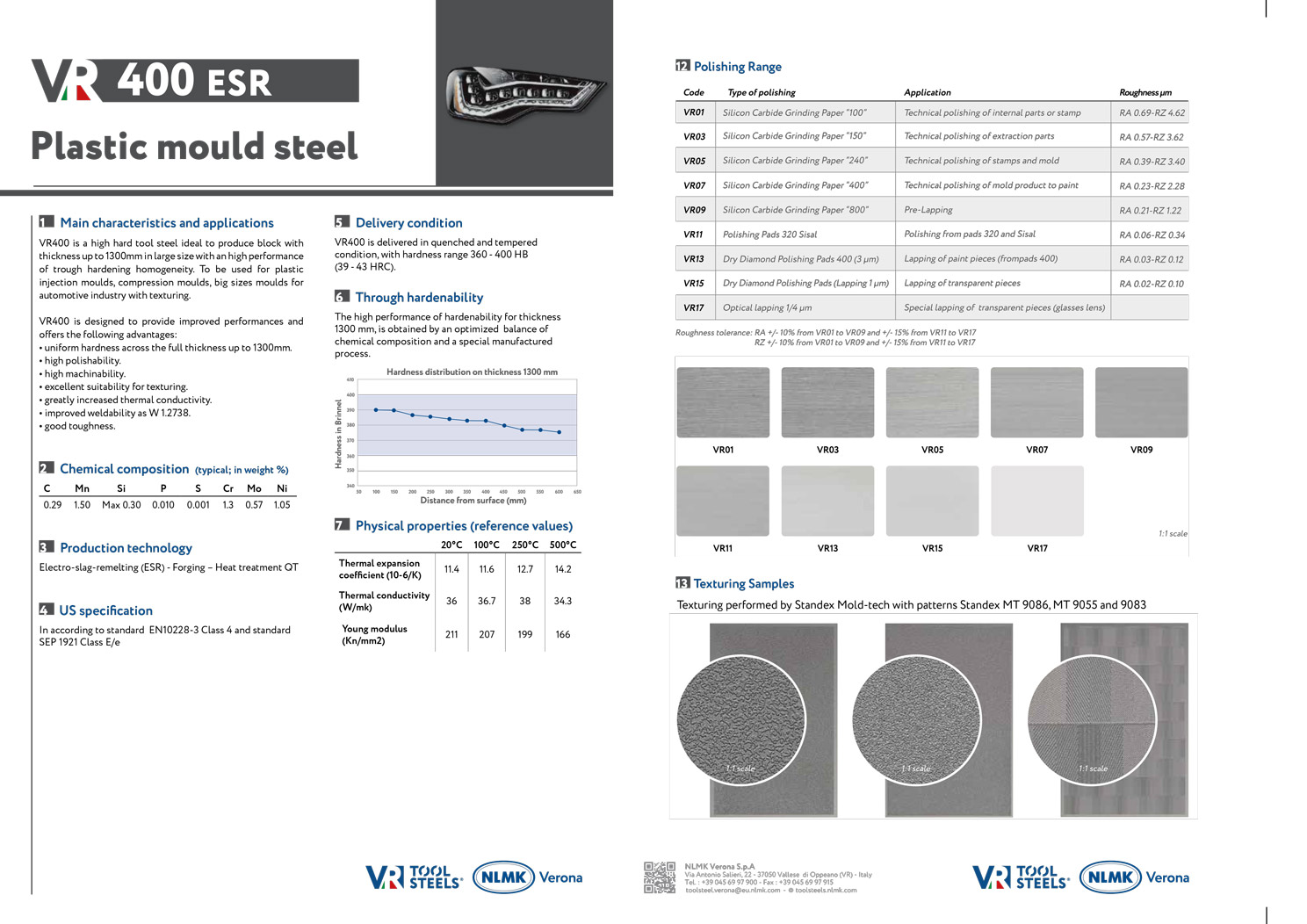

Chemical Composition:

| C | Mn | Si | Cr | Ni | Mo | P | S | P+S | V | W |

| 0.29 | 1.50 | 0.08 | 1.3 | 1.05 | 0.57 | 0.010 | 0.001 | – | – | – |

HARDNESS:

| HB | HRC |

| 360 – 400 | 38 – 42 |

TECHNICAL PROPERTIES :

| Machinability | Polishability | Texturability |

| ●● | ●●●●● | ●●●● |

Applications:

Very high Gloss demands such as injection moulds, compression moulds, Lighting moulds, Clear Articles.